-

******* To read about the changes to the marketplace click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FAIL SAFE SUMP opinions needed

- Thread starter itz216

- Start date

Chuck Spyropulos

Non-member

You also want to avoid straight vertical drops. problem with straight vertical drops is that you have air coming up and water going down if the water and air can pass each other then you get flushing. Pipes should meander

I have vertical drops in my system and have no problems with noise or siphons whatsoever. As long as the pipe diameter for the drains is larger than the pipe diameter on the returns there should be plenty of room for air and water in the drain pipes such that there is no noise. Of course, you always need to adjust the return flow from your return pump so that your drain pipes, whatever their capacity, can handle the water flow into the tank from the return pump. Having mulitple drain pipes that are larger than the return pipe diameter allows a higher return pump flow rate without noise.

delta

Impatient Reefer

Yes but your tank is sort of built into a wall. Someone with a free standing tank might not want it too far from the wall. By not running the pipe completely vertical they can push the envelope. That is why I prefer spa flex

Not everyone has the room for a 3"+ drain.

But like I said before some of it comes down to the person.

Not everyone has the room for a 3"+ drain.

But like I said before some of it comes down to the person.

One design feature I put in every sump I make, and it goes right to your title. "Fail Safe" (although ...is there such a thing ?  )

)

As drawn your sump will only move water when full, if you shorten the first and last baffles in each set to just over the sand bed height water will flow until it gets down to that point.

In the event of a water leak/ overflow this could save your reef. As much as we don't like water on the floor 10 gallons on the floor and reef still flowing is waaaayyy better than 5 gallons on the floor and no flow.

As drawn your sump will only move water when full, if you shorten the first and last baffles in each set to just over the sand bed height water will flow until it gets down to that point.

In the event of a water leak/ overflow this could save your reef. As much as we don't like water on the floor 10 gallons on the floor and reef still flowing is waaaayyy better than 5 gallons on the floor and no flow.

itz216

Non-member

The idea of using 1 1/2" Spa Flex for the drains hold some appeal ( seems large enough to take a snail and some water!) ...I'm assuming, rigid pvc for the return, correct?

Anybody have/lend the (2) glass cutter/bits ( for the 1" return and the 1 1/2" drain) I'll need? I'll throw in a well behaved RBTA and return ship the bits::

Thx everybody for all the help. I sheetrocked my whole house in 5/8" - and promised I'd never do that again! With some luck and all the great input - fingers crossed, I won't have to ...

Anybody have/lend the (2) glass cutter/bits ( for the 1" return and the 1 1/2" drain) I'll need? I'll throw in a well behaved RBTA and return ship the bits::

Thx everybody for all the help. I sheetrocked my whole house in 5/8" - and promised I'd never do that again! With some luck and all the great input - fingers crossed, I won't have to ...

Chuck Spyropulos

Non-member

Spa Flex

I used Spa Flex for "close to the tank" runs for returns and drains where there otherwise would elbows. For straigtht long runs to my remote sump I used rigid PVC.

The idea of using 1 1/2" Spa Flex for the drains hold some appeal ( seems large enough to take a snail and some water!) ...I'm assuming, rigid pvc for the return, correct?

I used Spa Flex for "close to the tank" runs for returns and drains where there otherwise would elbows. For straigtht long runs to my remote sump I used rigid PVC.

If your return flow rate is much greater than the skimmer's pump rating you may lose alot of skimmer effectiveness. I originally had 2 - 1" drain lines and I ended up taper them down to 2- 3/4" as they entered the sump.

As for sump capacity, use the RC calculator to determine how much total water volume your sump will hold in the event oif a power outage. Based on this determine how far down the display water column equals the sumps water capacity and that is the lowest in the tank that you should drill the drain (and return) holes - any deeper and you will have an overflow during a power outage.

Agree on the durso pipes for the drains - already discussed.

You may want to slot the top of the overflow box so that it is allowed to act as a surface skimmer rather than fully submerse under water and catch the top water level (hope that makes sense).

Agree on the syphon break on the return - best advise provided - I learned the hard way! I even had an in-line check valve for the return path and it didn't prevent the syphon - I hate when that happens! You can add the syphon breaks as previosuly advised as well as aim the return adapter so that it points high in the water column.

Also, be sure to maximize the last chamber where the return pump sits to minimize how frequently top off water is required. Speaking of which I strongly recommend you plan for a ATO system - spend less time replacing water and more time enjoying your tank.

Have fun with the project and let us know how it goes.

As for sump capacity, use the RC calculator to determine how much total water volume your sump will hold in the event oif a power outage. Based on this determine how far down the display water column equals the sumps water capacity and that is the lowest in the tank that you should drill the drain (and return) holes - any deeper and you will have an overflow during a power outage.

Agree on the durso pipes for the drains - already discussed.

You may want to slot the top of the overflow box so that it is allowed to act as a surface skimmer rather than fully submerse under water and catch the top water level (hope that makes sense).

Agree on the syphon break on the return - best advise provided - I learned the hard way! I even had an in-line check valve for the return path and it didn't prevent the syphon - I hate when that happens! You can add the syphon breaks as previosuly advised as well as aim the return adapter so that it points high in the water column.

Also, be sure to maximize the last chamber where the return pump sits to minimize how frequently top off water is required. Speaking of which I strongly recommend you plan for a ATO system - spend less time replacing water and more time enjoying your tank.

Have fun with the project and let us know how it goes.

I would put one of these on the tank if you're really worried about spill over.

I have one and if the water level rises for any reason the return pump shuts off.

http://autotopoff.com/products/ST1/index.htm

I too use a float switch in my display to shut off my return pump if the display water level starts to rise for any reason to prevent flooding. If you have any fear that the drain could get potential clogged, such a safeguard can be a major carpet/floor saver.

itz216

Non-member

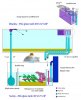

Updated layout.

How high do the Dursos need to be above the water line? How big is the hole on top?

Do the drain screens inside the overflow box need to break the surface?

Moved heater to skimmer section ...in case the Mag5 ever emptied that section.

Moved HOB skimmer outside of sump.

How high do the Dursos need to be above the water line? How big is the hole on top?

Do the drain screens inside the overflow box need to break the surface?

Moved heater to skimmer section ...in case the Mag5 ever emptied that section.

Moved HOB skimmer outside of sump.

Attachments

MikeG

Non-member

I always make the holes adjustable. Use a PVC cap on the top of the durso that slips over the PVC sticking up and not a plug. I then drill through the side of the cap instead of the top so it goes through both the cap and the PVC that the cap is slid onto. Now just twist the cap to open or close the hole. Make sure the cap isn't on real tight so that it can be turned easily before drilling. Let me know if you need a pic to understand that.Updated layout.

How high do the Dursos need to be above the water line? How big is the hole on top?

Do the drain screens inside the overflow box need to break the surface?

Also make sure to leave a good amount of room like an inch or so between and under baffles. Small spaces will increase velocity and bring all the bubbles with it. I would lower the last over baffle to be the same height as the over baffle before it. The under baffle inbetween can be as high as you mwant. I usually have under baffles come almost to the top of the tank. And lastly you will want the running water level to be several inches above you last over baffle to allow for evaporation before having the water level drop in that section. Your first over baffle sets the water height in the skimmer sectuion so you don't need to worry about water level changes. This will give a little added cushion before the return pump would run dry from any unforseen problem.

Last edited:

Sherri

Non-member

Just to add another idea in -- I like this design and have modified on my new 180g system:

http://reefcentral.com/forums/showthread.php?s=&threadid=1310585&perpage=25&pagenumber=1

http://reefcentral.com/forums/showthread.php?s=&threadid=1310585&perpage=25&pagenumber=1

Similar threads

Sponsors

Acro Garden

All Things Aquatic

Backwoods Reefs

Beantown Reefers

Blue Light Aquatics

Bull Reef Aquaculture

Classic Corals

Corals Kingdom

Crazy Corals

Cultivated Reef

Daves Corals

Frag Freaks

Frank's Frags

Joe's Fishy Business

Love The Reef

Mofo Corals

NEMO

On Point Corals

ReefBum

Reef Exclusive

The Coral Farm

Ultimate Corals

Wet Pets Emporium

WickedCoralGarden

All Things Aquatic

Backwoods Reefs

Beantown Reefers

Blue Light Aquatics

Bull Reef Aquaculture

Classic Corals

Corals Kingdom

Crazy Corals

Cultivated Reef

Daves Corals

Frag Freaks

Frank's Frags

Joe's Fishy Business

Love The Reef

Mofo Corals

NEMO

On Point Corals

ReefBum

Reef Exclusive

The Coral Farm

Ultimate Corals

Wet Pets Emporium

WickedCoralGarden