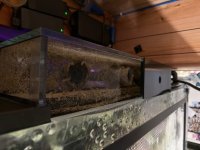

I am STRESSED. Did a water change last night on my 250g. Everything was smooth up until the time to turn return pump back on. Noticed a really loud humming vibration noise. Was only running at 50%. Pump is under a year old (Sicce SDC 7.0). I broke down the pump and noticed no issues, everything was clean. I noticed most the vibration noise coming from the soft silicone tubing that connects to the barb then hard plumbing. I have been recommended to just remove the silicone tubing and plumb hard plumbing the entire return line.

Second problem is… as I was messing around with my return line. I got a water drop on my head… lol my bulk head started dripping!! I assume from me moving the return line while diagnosing where the vibration noise was coming from. Bulk head did not like that at all.

Problem is I am very anxious about redoing this and would much rather prefer someone with more knowledge to help! If anyone who is knowledgeable has some free time anytime and would like to come help me. I would appreciate it so much. I can buy whatever parts I need to do the work so it’s just a matter of assistance with the rework. Can supply pizza and beer and even pay for your time. Thanks in advance.

Second problem is… as I was messing around with my return line. I got a water drop on my head… lol my bulk head started dripping!! I assume from me moving the return line while diagnosing where the vibration noise was coming from. Bulk head did not like that at all.

Problem is I am very anxious about redoing this and would much rather prefer someone with more knowledge to help! If anyone who is knowledgeable has some free time anytime and would like to come help me. I would appreciate it so much. I can buy whatever parts I need to do the work so it’s just a matter of assistance with the rework. Can supply pizza and beer and even pay for your time. Thanks in advance.