In my constant quest to improve on the setup I was planning a desk/stand setup for the tank and sump and while looking at ideas several setups popped up about DIY aluminum extrusion stands and it got me to thinking. I used tinkercad to design a rough idea and I like that it adds flexibility and easy customization compared to a wooden stand. I know @BiGGiePauls33 and others have aluminum extruder stands but I was curious if anyone has ever made one themselves?

I am looking to use 3030 bar and I was going to try and do a "floating" shelf for my 10 gallon tank and I wasn't sure if that would be strong enough? I had thought about using 80/20 as that is just a tad stronger but man it is triple the cost of 3030!

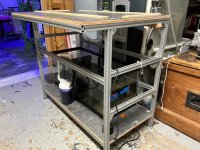

Here is a quick sketch I made of the set up I was thinking of doing that involved the 80/20 to hold up the 10 gallon tank. I found some free .stl files for the 3030, 2020 and 80/20 so I was able to create it pretty easily. It's not perfect by any means but I wanted to get a rough design so I could figure out how much I would need to try and get a rough cost. It appears like it would be a little under $500 including the aluminum pieces, angle brackets and various connecting pieces and does not include panels...

Orange containers top shelfs are phytoplankton cultures that I would want to display. Orange ones under are the copepod cultures. Tank is on the right with sump underneath. 10 gallon tank is elevated and the 5.5 gallon ATO reservoir is bottom left and plan would be to make that section into drawers/storage area.

I am looking to use 3030 bar and I was going to try and do a "floating" shelf for my 10 gallon tank and I wasn't sure if that would be strong enough? I had thought about using 80/20 as that is just a tad stronger but man it is triple the cost of 3030!

Here is a quick sketch I made of the set up I was thinking of doing that involved the 80/20 to hold up the 10 gallon tank. I found some free .stl files for the 3030, 2020 and 80/20 so I was able to create it pretty easily. It's not perfect by any means but I wanted to get a rough design so I could figure out how much I would need to try and get a rough cost. It appears like it would be a little under $500 including the aluminum pieces, angle brackets and various connecting pieces and does not include panels...

Orange containers top shelfs are phytoplankton cultures that I would want to display. Orange ones under are the copepod cultures. Tank is on the right with sump underneath. 10 gallon tank is elevated and the 5.5 gallon ATO reservoir is bottom left and plan would be to make that section into drawers/storage area.