Has anyone ever built one of these? I want to build one, but can only find the 4.5" Acrylic tube online. Has anyone ever built them differently than all the DIY plans show? It doesn't look like an overly complicated device to build, so I was looking for Ideas on how to do it without the tube. It looks like the acrylic tube is only needed to see when your kalkwasser is low. I was thinking maybe I could use a clear plastic filter housing for the bottom half, and then regular PVC for the top half. What do you all think?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nilsen Reactor question

- Thread starter smcnally

- Start date

I think a filter housing would be too small.

I made one out of 6" acrylic tube. Very easy DIY project. You can see pictures in the DIY showcase thread.

Nate

I made one out of 6" acrylic tube. Very easy DIY project. You can see pictures in the DIY showcase thread.

Nate

I'm not sure if this would work for kalk powder, but you may want to look into a Phosban reactor... they're relatively cheap (around $35) and they're basically a fluidized bed type of reactor, where the water flows through the media from the bottom to the top, and the media tumbles around and tends to settle at the bottom... kalk may be too powdery/light to work well, though, but may be worth a try.

Nuno

Nuno

I don't think Kalk would work in those. At least not without modification. It's critical that you don't pump kalk paste into your system from a kalk reactor, so they need to be tall enough to get good separation of the solids from the saturated solution, before it exits the top of the chamber. Don't think the reactor would be big enough.

Nate

Nate

Not yet. I keep meaning to make a thread about that (or an article for cindy) but I can't seem to get around to it. It's very basic though. There's a bottom glued onto the tube, a cross-brace about 3/4 up the tube, with a hole that the minijet output sits in. A piece of 1/2" PVC extends the output down to the bottom of the chamber, where it is glued, with holes drilled in the PVC just above the bottom. The top has a flange and a lid with an o-ring and 10 wing nuts/bolts to seal the top. There are two John Guest fittings tapped into the top. One has 3/8" rigid tube (from a faucet stem tube) extending to the bottom for the RODI feed. The other is the kalk output, and is fed right off the top, where the solution will be clearest. The cord for the powerhead is sealed through a hole in the top with West Epoxy. The powerhead is turned on twice for one minute (morning and evening).

Works great. Cost about $30 because I had most of the acrylic scrap lying around, took about one evening.

Nate

Works great. Cost about $30 because I had most of the acrylic scrap lying around, took about one evening.

Nate

Square should be fine. You'll probably want to use gasket material instead of an o-ring to prevent leaks at the top.

You can do the o-ring groove with a router table too. Actually the whole thing can be done on a router table (and a drill press or hand drill). Not much harder, just need to make a circle cutting jig that you can spin a piece of acrylic on, and adjustable so you can move the axis point closer or further from the bit, depending on the size of circle you need to cut.

Nate

Nate

You need to know when the lime is running out. Also I like to see how it's mixing and settling to ensure that suspended kalk slurry isn't getting pumped into the tank. I'd be a little nervous if I couldn't see the inside of my reactor from time to time.

Making it square out of flat acrylic should work fine though. If you're looking to save money I think that's a better way to go.

Nate

Making it square out of flat acrylic should work fine though. If you're looking to save money I think that's a better way to go.

Nate

If you need round templates for the build someone can stop by here on saturday and I'll find or make them for you.

Nate

Nate

Ok guys, I would love to tag along on this one if there?s room for one more. I looked at some Nilson plans and it seems to be the best design for a drip. I need to get my parameters stable as some of my stock is looking not so healthy. Who ever is sponsoring this one let me know if I can tag along.

Thanks?Rich

Thanks?Rich

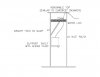

would a design like this work? it is my understanding you want the water in the middle to go into the tank. This would also eliminate the need for any gaskets and make refilling it easier. The RO/DI in would be attached to an auto-top off switch and the mixing pump would run a few times a day.

Attachments

I am pretty sure that you want to have the reactor sealed so that you minimize precipitation of the kalk water with CO2 from the air when mixing. Personally, I like the one that Nate built.

-Brian

-Brian

Similar threads

- Replies

- 13

- Views

- 5K

- Replies

- 2

- Views

- 279

- Replies

- 1

- Views

- 145